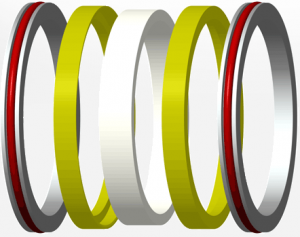

Meco shaft seals are designed for process equipment, there are special challenges in sealing rotating shafts. Applications include e.g. screw conveyors, conveyors, mixers, drying drums, extruders, paper pulp and potentially explosive atmospheres in accordance with ATEX standards.

The Meco seal can be made from a variety of materials that are best suited for those process environments.

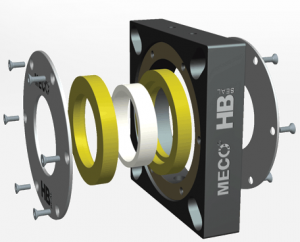

The MECO HB Seal model is ideal for screw conveyors/scrolls, small blenders, bucket elevators, and similar rotating equipment used in bulk process industries.

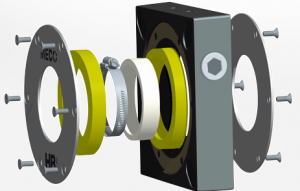

The MECO HC Seal model is the best air-free choice in sealing technology for screw conveyors/scrolls, small blenders, bucket elevators, and similar rotating equipment used in bulk process industries.

Several MECO seal models are available with ATEX certification. Common to all are a risk assessment, thermal testing and documentation, combined with a variety of protective measures.

The MECO AH Type-2 model is the best choice for fitting a split seal in limited space on small to large shaft diameters.

Where axial or linear space is limited, the MECO EA Type-1 seal model is the solution for sealing wet abrasive slurries encountered in pulpers, agitators, cylindrical blenders, paddle mixers, holding vessels, flocculators, mixing conveyors and similar rotating equipment. When linear space is available our EP Type-1 model should be considered.

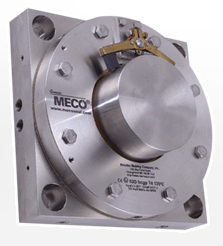

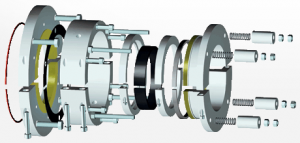

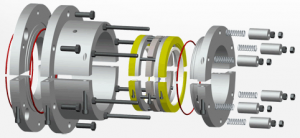

The MECO EA Type-2 seal model is ideal for large solvent extractors, pressurized conveyors, holding tanks or similar rotating equipment. Fitment for some blenders, dryers & sigma mixers is also possible. Common industries that use the seal are plastics, oilseed processors, chemicals, carbon anodes, metals, pharmaceuticals and food processors.

Where axial or linear space is available, the MECO EP Type-1 seal model is the solution for sealing wet abrasive slurries encountered in pulpers, agitators, cylindrical blenders, paddle mixers, holding vessels, flocculators, mixing conveyors and similar rotating equipment. When linear space is limited, our EA Type-1 model should be considered.

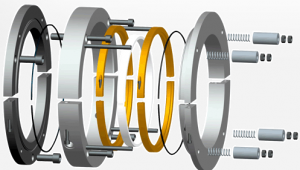

The MECO EP Type-2 seal is ideal for single- or twin-shafted extruder-compounders, plow blenders, paddle blenders, conveyors and similar rotating equipment used in the plastics, chemical, metals, pharmaceutical, food and other process industries.

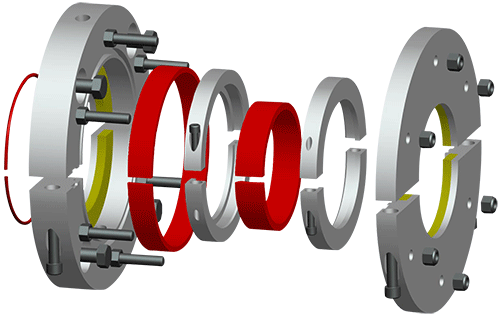

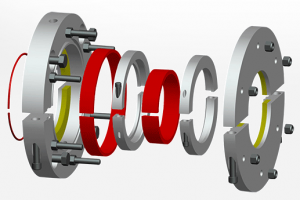

The MECO EP Type 3 split seal model is ideal for dryers, sigma mixers, plow blenders, paddle blenders, reactor vessels, extruder-compounders and similar rotating equipment used in the chemical, plastics, metals, pharmaceutical and other process industries.

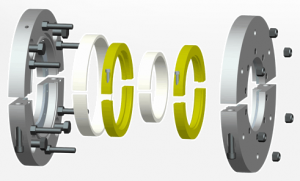

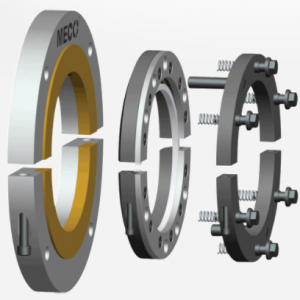

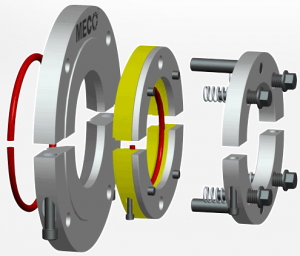

The MECO OFS Type-1 seal is frequently the best, fully-split seal for vacuum, low pressure, and abrasive applications. The design tolerates both runout and thermal growth at moderate speeds.The OFS Type-1 split seal is ideal for top-entry agitators, crystallizers, dryers, pan mixers, blenders, hoppers and similar rotating equipment used in the petrochemical, plastics, metals, minerals and other process industries.

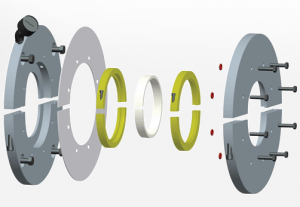

The patented MECO OFS Type-2 model is the best choice in many sealing applications for low to moderate speed equipment. The OFS Type-2 seal model is ideal for blenders, mixers, cookers, conveyors and similar rotating equipment used in the food, pharmaceutical, chemical, plastics, metals, and other bulk process industries.

The MECO-MB seal model is an elastomer driven, contacting face seal designed to fit inside of an existing stuffing box. The MECO-MB is a proven solution for service on rotary feeders and airlocks in abrasive service, temperatures up to 260C (500F) and up to a 1 bar (100 kPa or 15 psig) pressure differential.