Posted on June 24, 2024 by Ramona Westersund - Uncategorized

KLINGER Finland’s product marking equipment and Universal Robots’ collaborative robots (cobots) offer an efficient and customized way to automate product marking processes. Collaborative robots are suitable for use in even the most challenging labeling, inkjet, or laser marking needs and environments. With cobots, various marking applications can be fully tailored to the customer’s specific requirements, ensuring accurate and reliable performance in all conditions.

KLINGER Finland delivers customized marking automation solutions on a turnkey basis.

Features

- Customizable solution for customer-specific needs

- Can be integrated with almost all KLINGER Finland’s inkjet printers, laser marking, and labeling devices

- Can be combined with any Universal Robots collaborative robot

- Automates even the most challenging labeling, inkjet, or laser marking needs

- Flexible applications, e.g.

- Moving the product to the marking device and marking all its sides

- Laser markings on multiple surfaces

- Picking up labels from the labeling device and attaching them to packages

Technical Specifications

- Payload without gripper max: 30 kg

- Reach: 500 – 1750 mm

- Pose repeatability (ISO 9283): ± 0.03 – 0.1 mm

- Noise level: Below 60 – 65 dB

- Cleanroom ISO classification: 5

- IP classification (arm): IP54 – IP65

- Power consumption: About 100 – 350 W with a typical program

- Tool flange connector type: M8 | M8 8-pin female

- Operating temperature range: 0 – 50˚C

- Operating humidity: 90% RH (non-condensing)

Benefits of Marking Automation Solutions

- Automation improves efficiency: KLINGER Finland’s marking automation solutions increase the efficiency of the entire production process easily, safely, and flexibly.

- Ensuring operational continuity: Collaborative robots can operate around the clock, minimizing the risk of line downtime and ensuring smooth operation of the production line.

- Eases complex marking needs and works in challenging environments: Cobots can be integrated into existing production environments, ensuring seamless deployment and operation even in difficult conditions.

- Reducing manual labor: Robots handle the marking, freeing employees for other tasks and reducing manual labor.

- Minimizing errors: Automation reduces the risk of human errors and improves the accuracy and reliability of the process. Marking automation ensures precise and consistent label or marking placement every time.

Link to the Manufacturer’s Website

Universal Robots

Posted on June 24, 2024 by Ramona Westersund - Uncategorized

The Intrex Easy Stack palletizing unit efficiently automates the pallet packaging process. This palletizing unit, integrated into the customer’s production environment, enables simultaneous palletizing of two pallets, ensuring production continuity. The palletizing unit works with a Universal Robots collaborative robot (cobot) and is fully customizable to meet the customer’s needs. The Intrex Easy Stack palletizing unit is easily reprogrammable, making it flexible and versatile for various tasks and applications.

KLINGER Finland delivers and assembles the palletizing unit on a turnkey basis. We offer expert support and service throughout the entire lifecycle of the device.

Features

- Packs boxes onto two pallets

- Does not necessarily require safety fences, thus saving floor space

- Fully automatic extendable cobot column; Compatible with all Universal Robots collaborative robots: most commonly used models for palletizing are UR10e, UR20, and UR30

- Unlimited stacking possibilities – easy to reprogram

- Can be combined with accessories such as feed conveyors, marking devices, and custom grippers, etc.

- Includes a lifetime license for Intrex’s own Easy Stack pallet design software, used directly from the device’s touchscreen

- Safe and easy to use

Technical Specifications

- Payload without gripper max: 30 kg

- Reach: 500 mm – over 2500 mm with telescopic pedestral

- Pose repeatability (ISO 9283): ± 0.03 – 0.1 mm

- Noise level: Below 60 – 65 dB

- Cleanroom ISO classification: 5

- IP classification (arm): IP54 – IP65

- Power consumption: About 100 – 350 W with moderate operating settings

- Footprint: Ø 128 – 245 mm

- Tool flange connector type: M8 | M8 8-pin female

- Operating temperature range: 0 – 50˚C

- Operating humidity: 90% RH (non-condensing)

Benefits of the Intrex Easy Stack Palletizing Unit

- Automation improves efficiency: The Intrex Easy Stack palletizing unit helps increase the efficiency of the entire production process easily, safely, and flexibly.

- Ensuring operational continuity: The palletizing unit helps minimize the risk of line downtime, ensuring smooth operation of the production line.

- Versatility and integrability: The palletizing unit can be integrated into existing production environments, ensuring seamless deployment. When needs change, the palletizing unit is easy to reprogram.

- Reducing worker strain: Palletizing automation reduces the physical strain on workers, which is especially important in handling heavy loads.

- Ease of use and intuitiveness: The palletizing unit is designed to be user-friendly, making it easy to use without extensive training, even for individuals with no prior experience with collaborative robots.

- Minimizing errors: Automation reduces the risk of human errors and improves process accuracy and reliability.

Link to the Manufacturer’s Website

Intrex

Universal Robots

Posted on June 24, 2024 by Ramona Westersund - Uncategorized

The Easyrobotics Easypalletizer palletizing unit automates the pallet packaging process, reducing the physical strain on workers and bringing flexibility and speed to production. Thanks to the ready-to-use Rocketfarm Pally palletizing software, defining the arrangement of goods on the pallet is quick. The Easyrobotics EasyPalletizer palletizing unit is compatible with all Universal Robots collaborative robots (cobots). The cobot can simultaneously work with two pallet, and with the telescopic pedestral, it can reach over 250 cm in height. The palletizing platform can be moved from one workstation to another as needed.

KLINGER Finland delivers and assembles the palletizing unit on a turnkey basis. The complete package ensures safe, easy, and fast use. We offer expert support and service throughout the entire lifecycle of the device.

Features

- Floor-level palletizing for two pallets

- Does not require safety fences, thus saving floor space

- Compatible with all Universal Robots collaborative robots: most commonly used models for palletizing are UR10e, UR20, and UR30

- Load transfer stations for mobile robots from conveyors or other fixed units

- Unloading/loading transfer systems

- Movable palletizing cell, easy to install mechanically with a pallet truck

- Available with Rocketfarm Pally palletizing software

- Pallet detection: Four detection pins on each pallet site which ensure correct docking of pallet before starting palletizing

- Base options: SKF Liftkit or fixed pedestral

Technical Specifications

- Payload without the gripper max: 30 kg

- Reach: 500 mm – over 2500 mm with telescopic pedestral

- Pose repeatability (ISO 9283): ± 0.03 – 0.1 mm

- Noise level: Below 60 – 65 dB

- Cleanroom ISO classification: 5

- IP classification (arm): IP54 – IP65

- Power consumption: About 100 – 350 W with moderate operating settings

- Footprint: Ø 128 – 245 mm

- Tool flange connector type: M8 | M8 8-pin female

- Operating temperature range: 0 – 50˚C

- Operating humidity: 90% RH (non-condensing)

Benefits of the Easyrobotics Easypalletizer Palletizing Unit

- Production efficiency and flexibility: The Easyrobotics Easypalletizer palletizing unit brings flexibility and speed to production while reducing the physical strain on workers.

- Safety: Safe palletizing of products and fewer worker injuries.

- Ensuring operational continuity: The palletizing unit helps minimize the risk of line downtime, ensuring smooth operation of the production line.

- Flexibility in deployment: Movable palletizing cell, easy to install and use in different workstations.

- Ease of use and intuitiveness: Thanks to the Rocketfarm Pally palletizing software, arranging boxes is quick and easy.

- Minimizing errors: Automation reduces the risk of human errors and improves the accuracy and reliability of the process.

Link to the Manufacturer’s Website

Easyrobotics

Universal Robots

Posted on June 24, 2024 by Ramona Westersund - Uncategorized

Universal Robots’ collaborative robots (cobots), combined with KLINGER Finland’s product marking solutions, offer an efficient and flexible comprehensive solution for the palletizing and marking automation needs of the packaging industry. With UR cobots, companies can automate repetitive and time-consuming tasks, increasing productivity and improving working conditions.

Using cobots for palletizing tasks enables fast and precise handling of products, reducing errors and improving production line efficiency. Collaborative robots do not necessarily require safety fences around them, thus saving floor space. They can handle various products and easily adapt to production changes. Since cobots are designed to work in the same workspace as humans, leveraging palletizing and marking automation is easier for companies of all sizes.

In product marking automation, UR collaborative robots ensure accurate and consistent marking, reducing the risk of incorrect markings and improving product traceability. Cobots’ programming is intuitive, and their deployment is quick and effortless.

UR cobots offer a reliable and cost-effective way to improve palletizing and marking automation in production processes, helping companies stay competitive and meet the growing demands of the market.

Universal Robots’ mission is to make automation accessible to everyone, everywhere. Over 75,000 cobots have been deployed worldwide, and they are developed and manufactured in Odense, Denmark. Universal Robots is a clear market leader and pioneer in collaborative robotics, and the new fifth-generation cobots have taken the technology to a new level.

KLINGER Finland helps you choose the collaborative robot solutions and necessary accessories that best support and enhance your production.

Explore our solutions below and contact us!

Universal Robots Collaborative Robots

Learn more and compare different cobot models:

Posted on May 8, 2024 by Peter Jansson - Uncategorized

KLINGER PS pressure transmitter

Made with advanced glass micromelting technology, no risk of leakage due to the uniform structure.

Advanced digital temperature compensation function, wide operating temperature range.

Technical information:

Supply voltage 9~30VDC 5VDC 9~30VDC 9~30VDC 15~30VDC

Accuracy ±0.5%FS ±1%FS

Long-term stability (1 year) ±0.1% FS

Frequency response (-3 dB) 3.2 kHz

Overload pressure 300% FS

Burst pressure 500% FS

Mechanical vibration ±20g Effect (11 ms)

Operating temperature -40~+85℃

Temperature compensation -20~+85 ℃

Protection level IP65

Material 17-4PH

Stock models:

PS10 : 0..10BarG | G1/4 | 4..20mA | M12 | ±0.5%FS

PS250 : 0..250BarG | G1/4 | 4..20mA | M12 | ±0.5%FS

PS400 : 0..400BarG | G1/4 | 4..20mA | M12 | ±0.5%FS

Posted on April 24, 2024 by Peter Jansson - Uncategorized

Force sensors are most commonly used in weighing applications but they are available for a wide range of applications. Force sensors use strain strips, which change their resistance when they are stretched. The signal provided is amplified in the force sensor amplifier, which gives the final standard output signal.

Force sensors are most commonly used in weighing applications but they are available for a wide range of applications. Force sensors use strain strips, which change their resistance when they are stretched. The signal provided is amplified in the force sensor amplifier, which gives the final standard output signal.

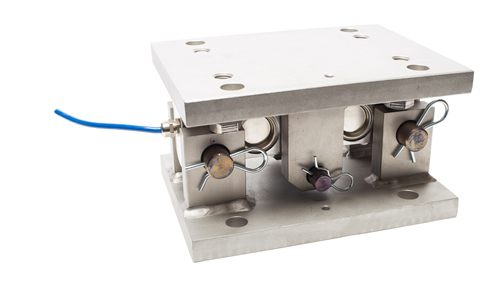

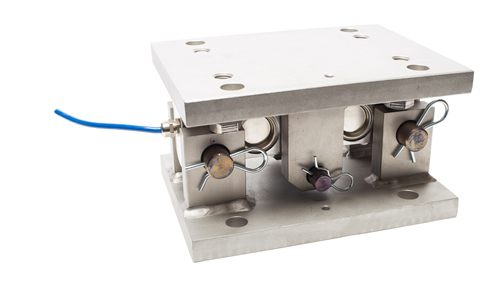

Vessel weighing problems solved simply and cost effectively. The MasterMount® is the latest addition to an innovative range of patented weighing assemblies which are designed with safety and ease of installation in mind.

Posted on April 24, 2024 by Peter Jansson - Uncategorized

ARTOSTM readhead with 2 options:

- Enclosed IP67 rated

- PCB-A module (with a vertical or horizontal connector)

ARTOSTM readhead with 2 options for the serial communication protocols:

- BiSS C

- SSI

- BiSS C + incremental ABZ (only available on the PCB-A version – DBR)

- SSI + incremental ABZ (only available on the PCB-A version – DBR)

7 different dimensions of absolute rings (SAR). Rings come in 2 versions, exposed and protected with a cover foil:From OD 57 to 478 mm

Absolute magnetic scale DS19 (length up to 2 m). A longer magnetic (up to 32 m) scale will be available once the stage-2 of the project is complete.

Available cable lengths: 1, 2, 3, 4, 5, 7, 10, 12 and 15 m

Posted on April 17, 2024 by Peter Jansson - Uncategorized

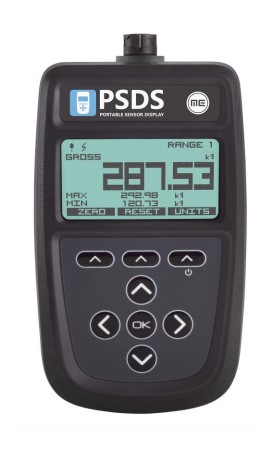

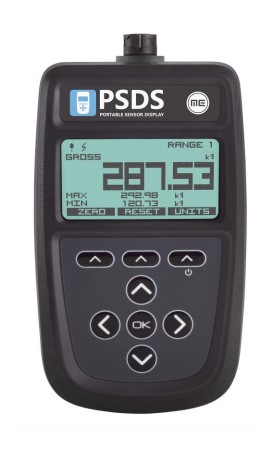

The hand-held PSDS model is a completely portable, battery-powered indicator designed to interface with our Whetstone bridge gauge sensors. It is especially useful for mobile testing.

- High resolution ADC providing sensitivity of between 7.5 mV/V to 480 mV/V. (3.3 VDC Excitation)

- Strain bridge connector for six wire connection plus TEDS support

- Two point calibration via the keypad or comprehensive calibration options via the toolkit.

- Simple keypad configuration or fully customised via toolkit software

- 128 x 64 dot matrix display with backlight

- USB port providing configuration, calibration, save & restore, live logging

- Measurement rate up to 2,400 SPS

- Ergonomic design with improved grip and shock protection

Posted on April 11, 2024 by tim.turtiainen@klinger.fi - Uncategorized

Key Features

- Up to 8 channels, 8 megapixel supported

- H.265, H.264, MJPEG codec supported

- 60Mbps network camera recording

- Plug & play with 8 PoE+ ports, 65W budget

- Maximum 1 HDD (up to 6Tb) supported

- HDMI local monitor

- P2P service (QR code connect) for easy remote access with Wisenet Viewer & Wisenet Mobile

- Dual track recording, 4K HDMI monitor out

Order number: EMSA4501 Hanwha Vision ARN-810S 8ch NVR

Posted on March 23, 2024 by Olli Turtiainen - Kopiotuote