Sealing

Reliability is utmost important in oil, gas and petrochemical industry. With KLINGER high quality certified sealing products, it’s possible to seal even most challenging applications safely and reliable.

KLINGER developed SENTRY-gasket is special product for O&G industry. It allows leak testing individually flanged joints without the need to pressurize the full system. This will save lot of time, efforts and resources during start-up preparation and will increase safety.

KLINGERexpert seal selection tool gives great support for correct seal selection and tightening moment definition. Our training course to assembly personnel (EN1591-4, certified) will be additional contribution for safe and smooth operation environment.

As a summary high quality seals, correct selection and qualified assembly personnel will guarantee high productivity (long mean time between failure) and safe working environment with optimal life cycle cost.

» Solutions for the most common sealing needs in the oil, gas and petrochemical industries:

|

|

|

|

|

| KLINGER Maxiflex | KLINGER Maxiprofile | KLINGER SLS | KLINGER PSM | KLINGER Milam |

|

|

|

||

| Metal gaskets | Graphite packings | Glass fibre fabrics |

Valves

From our wide range of product portfolio, you can find suitable valves for gas, flammable liquid and chemicals. In oil and gas production plants safety and equipment’s reliability is crucial. Valves ATEX – and Fire Safe standards as well fugitive emission standards TA -Luft and ISO 15848 are something to take in account selecting suitable products.

» Solutions for the most common valve needs in the oil, gas and petrochemical industries:

| Wedge gate valves | Globe valves | Check valves | Ball valves | Butterfly valves |

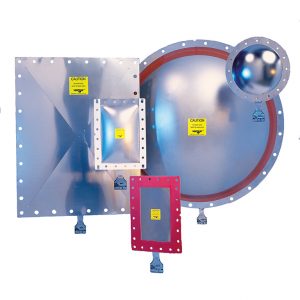

Rupture discs and explosion protection

Protect your personnel and applications from explosions and pressure caused ruptures with our range of rupture discs and explosion protection equipment. A rupture disc evens out the overpressure in an application.

» Solutions to the most common rupture disc and explosion protection applications in the oil, gas and petrochemical industries:

|

|

|

||

| Rupture discs | Explosion protection | Suppressing systems |

Camera surveillance

Our range of surveillance cameras includes cameras, recorders and monitors for the oil, gas and petrochemistry industries. We are able to customize the system according to the customer’s needs whether it is the renewal of the whole factory surveillance or the surveillance of the local process of 4 cameras on one screen. The Ag Neovo SX and RX series metal-shell safety screens we have been supplying to the industry for decades are suitable for 24/7 use. Monitors are affordable with a life cycle thinking model, through their long service life. Our selection includes e.g. analog HD, IP and HD-SDI system cameras, all with their own most suitable applications.

Examples are refrigerated firebox cameras, viewing through a sight glass or visual remote monitoring of the cylinder level gauge with a camera, and ATEX rated cameras.

Calibration

Measuring and monitoring processes enables production optimization and better management. These can be used to improve the efficiency and operation of the production plant. It is reasonable to take care of the accuracy and reliability of measuring instruments with regular calibration.

» Solutions for the most common calibration applications in the oil, gas and petrochemistry industries:

|

|

|

| Temperature calibrators | Pressure pumps |