Sealing

Pulp and paper mills have various stages and chemical processes, which require special know-how in industrial sealing. The gaskets and seals need to be able to withstand severe industrial conditions, such as corrosive media and high rotational speeds. Our product range has just the right solution for each stage of the process.

KLINGER high quality certified sealing products range offers just right solution for each stage of the process from clean water applications to even most challenging applications. KLINGERexpert seal selection tool gives great support for correct seal selection and tightening moment definition. Our training course to assembly personnel (EN1591-4, certified) will be additional contribution for safe and smooth operation environment.

As a summary high quality seals, correct selection and qualified assembly personnel will guarantee high productivity (long mean time between failure) and safe working environment with optimal life cycle cost.

» Solutions to the most common sealing needs in the pulp, paper and timber industry:

|

|

|

|

| PTFE-gaskets | Metallic gaskets | Fiber gaskets | Shaft seals |

Valves

Our wide range of valves contains the right product for each work stage in the pulp and paper industry, such as wood and pulp processing, causticising and whitening. Our specialist knowledge in the industry is very strong, and valves supplied by KLINGER Finland can be found in pulp and paper mills around the world.

» Solutions to the most common valve applications in the pulp, paper and timber industry:

|

|

|||

| Shut-off and control valves | Safety valves |

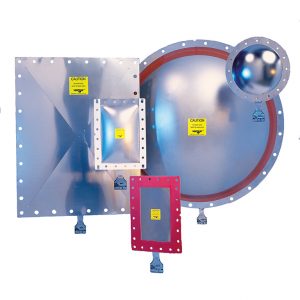

Rupture discs and explosion protection

Protect your personnel and applications from explosions and pressure caused ruptures with our range of rupture discs and explosion protection equipment. A rupture disc evens out the overpressure in an application, such as in bleaching or chemical processing. In pulp, paper and saw mills the danger of explosions is eminent as the three elements causing an explosion (dust, air and ignition) are present in many applications. With explosion protection you can minimise the damage of a potential explosion.

» Solutions to the most common rupture disc and explosion protection applications in the pulp, paper and timber industry:

|

|

|||

| Rupture discs | Explosion protection |

Calibration

The measuring and monitoring of processes enables the optimization of production as well as better control of the processes. These in turn improve the efficiency and operation of the facility. It is sensible to look after the accuracy and reliability of the measuring equipment with regular calibration.

» Solutions to the most common calibration needs in the pulp, paper and timber industry:

|

|

|

| Temperature calibrators | Pressure pumps |

Product marking

Make permanent markings on timber with our solutions, even on porous materials. With the right kind of ink the markings will even withstand the different after treatments of wood. Our product range also contains the right equipment and materials for the identification and marking of various types of paper products.

» Solutions to the most common product marking needs in the pulp, paper and timber industry:

|

||||

| Ink jet printers |

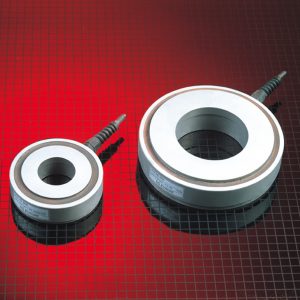

Process monitoring

Sensors and motors of machine automation

» Solutions to the most common machine automation needs in the pulp, paper and timber industry:

|

|

|

|

|

| Linear sensors | Inclination sensors | Force sensors | Stepper motors |