Product marking

In the food and beverage industry, a well designed packaging and product marking not only fulfills the industry requirements but also raises the interest of the consumer and influences the buying decision. With our solutions you can ensure that your product stands out from the competition and finds its way to the consumers shopping basket.

Typical product marking applications used in the food and beverage industry include best before dates, batch numbers, 2D codes, product labels and their automatic application, promotional labels, logistical markings on the external packaging, as well as food grade inks and other consumables.

KLINGER Finland complies with the Good Manufacturing Practice, which requires that food contact materials do not cause danger or harm to the consumer.

» Solutions to the most common product marking needs in the food and beverage industry:

|

|

|

|

|

| Ink jet printers | Laser marking machines | Thermal transfer overprinters | Labelling machines | Ventus Print & Apply |

Sealing

When it comes to food and beverage you need to be absolutely certain that no unwanted substances can enter the process. Our product range consists of certified gasket and sealing materials that have been proven suitable for use in food and beverage processes (FDA, EU, ISO). Gaskets and seals in food and beverage applications need to tolerate different kinds of media, such as milk fat of dairy products or phosphoric acid found in cola drinks. In addition, the gaskets and seals need to withstand the cleaning and sterilization processes that are characterise the food and beverage industry.

The clean production area of the KLINGER Group enables in its part certification according to the Food safety standard ISO 22000.

» Solutions to the most common sealing needs in the food and beverage industry:

|

|

|

|

|

| KLINGERtop-chem 2000 | KLINGERtop-chem 2003 | KLINGERtop-chem 2005 | KLINGERsoft-chem | KLINGER Sealex |

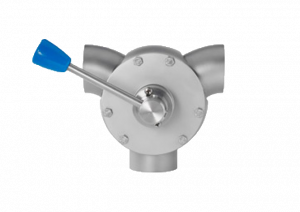

Valves

Valves in the food and beverage industry can be divided into two groups: valves in contact with the food product and valves used in the background processes. It is critically important that the valves in contact with the food product form a seamless and smooth link with the rest of the production line to prevent any opportunity for the medium to get trapped in the line and to eliminate any potential breeding grounds for bacteria to grow. Operating pressures are lower compared to other industry segments, and the strongest chemicals that food and beverage valves need to withstand are involved in the cleaning and sterilization processes.

Valves used in the background processes in the food and beverage industry are found here, whereas you can familiarise yourself with valves designed especially for the food and beverage industry by clicking the links below.

We also provide bespoke valves designed especially for your specific needs.

» Solutions to the most common valve applications in the food and beverage industry:

|

|

|

|

| Butterfly valves | Ball valves | Check valves | Manual shut-off valves |

|

|

|

|

| Double seat valves | Diaphragm valves | Arc valves | Pigging valves |

Process control

Calibration and instrumentation

Food and beverage producers need to adhere to strict hygiene and quality regulations while keeping their production agile and efficient. This requires the measuring and monitoring of processes. As the quality and safety of the food product depends on the accuracy of the measuring equipment and regular measurements, the reliability of the equipment needs to be ensured with calibration.

» Solutions to the most common calibration needs in the food and beverage industry:

|

|

|

| Temperature calibrators | Pressure pumps |